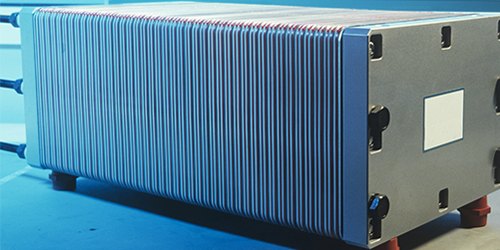

Our laboratory has built an extensive experience in the preparation and characterisation of components for proton exchange membrane fuel cells (PEMFCs), as well as in their testing in a hydrogen-fed laboratory-scale fuel cell test station.

PEMFCs are electrochemical devices able to transform the chemical energy stored in a fuel directly into electrical one. They achieve this goal by means of a simple redox reaction which involves the oxidation of hydrogen at the anode and the reduction of oxygen at the cathode, resulting in water and heat as the only byproducts. Therefore, PEM fuel cells are characterised by virtually zero emissions and by a theoretically high efficiency in their low-temperature operating range (60–90 °C). Moreover, their compact and modular design, coupled to a light weight and to the absence of moving parts, makes these devices potentially very reliable and extremely interesting for both portable and stationary power generation applications, especially in the transportation sector.

The core of a PEM fuel cell is its proton conducting membrane, which keeps anodic and cathodic compartments separated, allowing the reaction to occur and the flow of protons to be divided from the one of electrons, which can be exploited to perform useful electrical work. Our current line of research deals with the production of innovative graphene-oxide based proton conductors and with their morphological and functional characterisation, with the aim of developing electrolytes that can withstand fuel cell’s operating temperatures above 100 °C and a relative humidity of the supplied gases below 50%. These conditions would bring several benefits to fuel cell operation, among which a simpler water management and a faster reaction kinetics.

We also develop and characterise, both morphologically and electrochemically, water-repellent coatings for carbon-based gas diffusion layers. These components supply many crucial functions inside PEMFCs, such as providing a pathway for the homogeneous distribution of reactant gases over the electrodes’ active area and for the removal of by-product water. Hence, hydrophobicity is a fundamental property that must be properly controlled. Specifically, we study different polymer-based formulations of micro-/nano-porous inks for the hydrophobic treatment of such fuel cell components; we have also designed tailored both chemical and mechanical accelerated stress tests (ASTs) to assess the effect of their degradation on the fuel cell’s durability.